Home / All / Cable/Wire Cutting and Stripping Machine / Computer Wire Stripping Machine / TR-603HY Large Square Computerized Wire Stripping Machine+ Wire Winding Machine

TR-603HY Large Square Computerized Wire Stripping Machine+ Wire Winding Machine

Detail Information

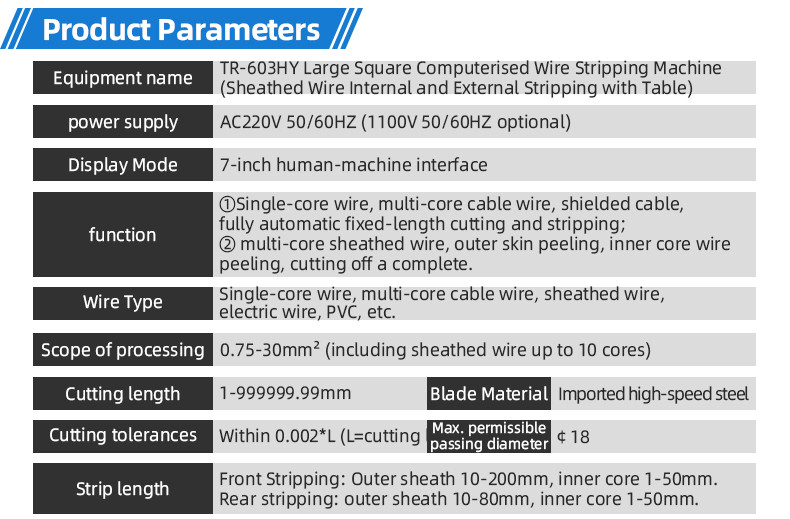

TR-603Y Large Square Computerized Wire Stripping Machine

Size and weight: 707x590x1140mm, 140kg

Display: 7-inch human-machine interface

Functions: ① single-core wire, multi-core cable wire, shielded cable, automatic fixed-length cutting, stripping;

② multi-core sheathed wire, outer skin stripping, inner core wire stripping, cutting off in one go.

Wire type: single-core wire, multi-core cable wire, sheathed wire, electric wire, PVC, etc.

Processing range: 0.75-30mm²

Cutting length: 1-999999.99mm

Cutting tolerance: 0.002*L or less (L=cutting length)

Stripping length: front stripping: outer sheathing fully stripped 10-200mm, inner core wire 1-50mm

Back stripping: outer sheathing fully stripped 10-80mm, inner core wire 1-50mm

Stripping speed: 3500 PCS/hour, (sheathed wire 900pcs/H) depending on the length and size of the wire

Feeding method: Belt feeding, no embossing and scratching on the cable. (with stripping pressurisation function)

Driving method: 16 wheel drive (feeding stepping motor, knife holder servo motor); optional servo feeding

Lifting operation: digital adjustment of the height of the pressure wheel

Allowed to pass through the maximum diameter: ¢ 18

Blade material: imported high-speed steel

Air source: 0.5Mpa clean air source

Remarks: Limit cut-off capacity 50 sq. ft.

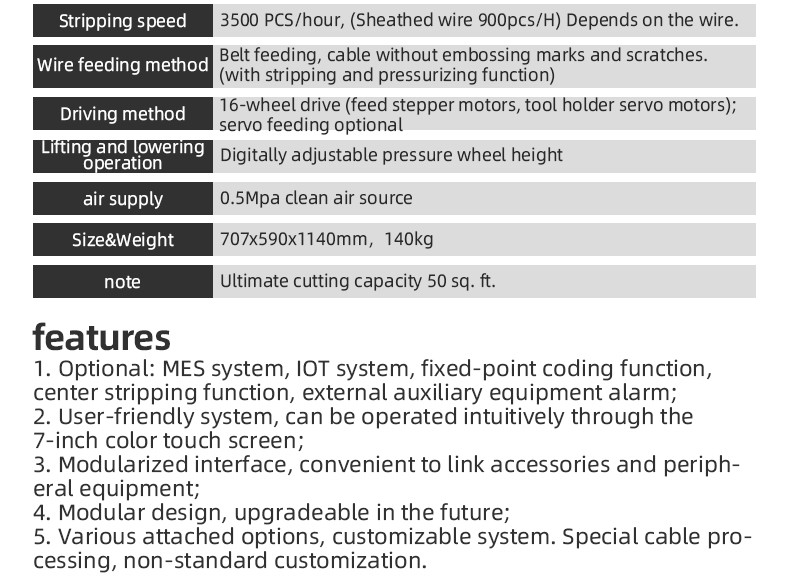

features

1. Optional: MES system, IOT system, fixed-point coding function, center stripping function, external auxiliary equipment alarm;

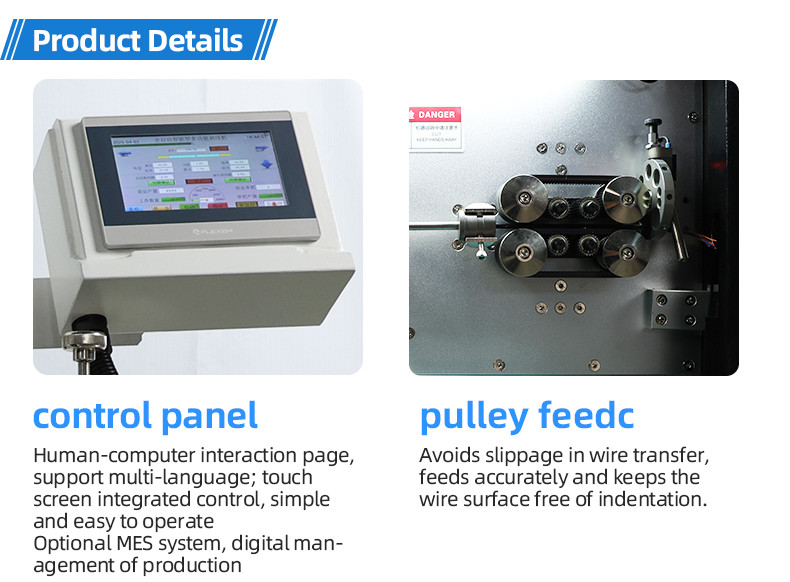

2. User-friendly system, can be operated intuitively through the 7-inch color touch screen;

3. Modularized interface, convenient to link accessories and peripheral equipment;

4. Modular design, upgradeable in the future;

5. Various attached options, customizable system. Special cable processing, non-standard customization.

TR-D381 Wire Winding Machine

Display Mode:Nixie Tube

Function Wire:Winding and Coiling

Wire Type:Electric Wires, Cables

Control Mode:Host Follow Control (can be used independently)

Winding Disc Diameter:380mm

Coiling Diameter:200-360mm

Coiling Speed:1.5M/s

Drive Mode:Servo Motor

Winding Completion:Detection None

Safety Device Pneumatic:Safety Door

Overall Dimensions:570x570x1000mm

Dongguan Turing Automation Technology Co., Ltd. was founded in 2020 and is located in Dongguan City, Guangdong Province. The company specializes in the production of: fully automatic terminal crimping machines, fully automatic automatic-automatic terminal crimping and tin-plating machines, ultra-quiet energy-saving terminal machines, silent copper strip machines, computerized wire cutting and stripping machines, coaxial wire stripping machines, fully automatic nylon cable tie machines, fully automatic winding and strapping machines, computerized heat shrinkable tube cutting machines, terminal machine molds, knife molds, and new energy automatic wire harness processing equipment, etc. It mainly serves wire harness processing enterprises in the automotive, motorcycle, electronics, household appliances, electrical and other industries.

We have rich industry experience and are a trustworthy supplier. Our holding/cooperative factories are equipped with advanced production equipment and skilled front-line employees. Fully aware that the company's development depends on product innovation and quality, we have established a quality management system that meets the requirements of international quality management systems. The company continuously launches original innovations based on market and customer needs, always maintaining the novelty and innovation of products. We think what customers think and prioritize what customers need. Providing customers with excellent services and meeting their needs is our eternal pursuit!

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Phone

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Fully auto crimp solder seal

- Semi auto Terminal Crimp Machine

- Cable/Wire Cutting and Stripping Machine

- Semi-automatic Pneumatic Wire Stripping Machine

- Computer Wire Stripping Machine

- Semi-automatic Coaxial Wire Stripping Machine

- Fully Automatic Coaxial Wire Stripping Machine

- Stripping and Bending Machine

- Threading Number tube Stripping Machine

- Electric wire stripping machine

- Insert tube print cable strip cut machine

- Cutting Machine

- Tape Bunding Machine

- Cable Winding and bunding Machine

- Inserting Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Wire Brushing Machine

- Heat Shrink Baking Machine

- Pay-off rack

- Copper busbar peeling machine

- Nylon cable tie bunding machine

- Copper Foil Wrapping Machine

- Welding Machine

- Cutting and Punching Machine

- Tin Dipping Machine

- Shielded Mesh Brushing, Turning & Cutting Machine

subscription

Please send your message to us

- *Name

- *Phone

- *Title

- *Content